From What Hi-Fi

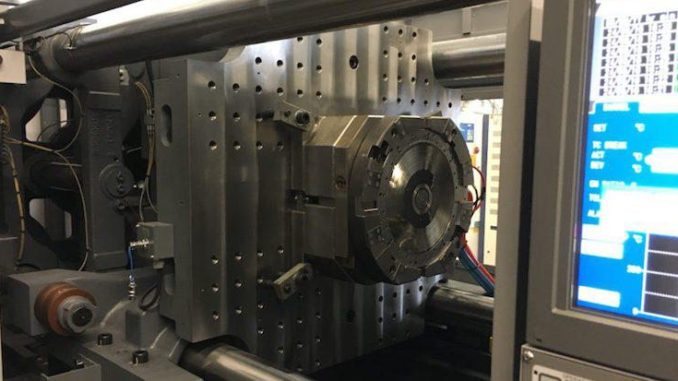

Pressing vinyl is a slow process, taking around 16 weeks to get from cutting floor to shop. However, Dutch company Symcon thinks it can speed up the process and improve sound quality by switching to injection moulding, where plastic mixture is injected into a mould.

The company, which specialises in CD manufacturing, is developing injection moulding technology, and has received a grant for the project, named Green Vinyl Records, from the European fund for innovation.

Because plastic is injected into the grooves, it is more accurate than the conventional pressing method, claims Symcon’s Harm Theunisse in an interview with Discogs.

Records can also be produced faster – Symcon is aiming to reduce the whole process to two weeks – and there are also improvements in sound quality and a reduction in the environmental costs of manufacturing.

However, the records aren’t as durable as conventional vinyl, and the material costs are slightly higher.

If you’re looking for some of those good ‘ol fashioned vinyl records, look no further – eil.com has a huge range of rarities, new releases, imports, reissues and more

Be the first to comment